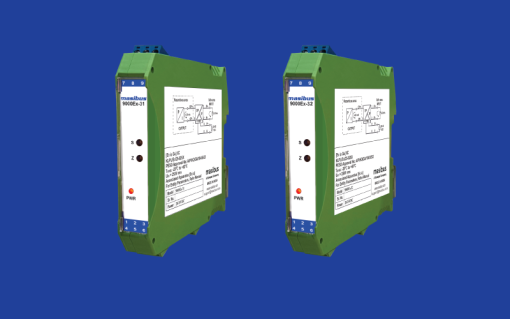

Smart Current Driver 9000Ex-31/ Ex-32

Smart Current Driver 9000Ex-31/ Ex-32

9000Ex-31 and 9000Ex-32 are single-channel Smart Current Drivers that provide a galvanically isolated 4–20 mA signal to the hazardous area, corresponding to a 4–20 mA input signal from the safe area. They repeat the current signal in another floating circuit to drive a hazardous area load, using isolating transformers that provide galvanic isolation. The Smart Current Driver operates SMART I/P converters, electric valves, and positioners in hazardous areas. It features high output capacity combined with a low voltage drop across its input terminals.

9000Ex-31 and 9000Ex-32 are single-channel Smart Current Drivers that provide a galvanically isolated 4–20 mA signal to the hazardous area, corresponding to a 4–20 mA input signal from the safe area. They repeat the current signal in another floating circuit to drive a hazardous area load, using isolating transformers that provide galvanic isolation. The Smart Current Driver operates SMART I/P converters, electric valves, and positioners in hazardous areas. It features high output capacity combined with a low voltage drop across its input terminals.

9000Ex-31 and 9000Ex-32 are DIN-rail mount Smart Current Drivers with a width of 17.6 mm. These Smart Current Drivers are classified as associated apparatus. Connections to the safe area and hazardous area are located on opposite sides of the enclosure, using plugs and sockets. Additionally, hazardous area terminals are color-coded in blue for easy identification.

It restricts the transfer of energy from unspecified non-hazardous area apparatus to intrinsically safe circuits by limiting voltage and current. The apparatus also enables bi-directional signal communication between hazardous and non-hazardous areas through the connection of a HART communicator.

Process controllers with a readback facility can detect open or short circuits in the field wiring. In the event of a fault condition, the current drawn at the input terminals drops to a preset level. 9000Ex-31 having similar construction to the 9000Ex-32 variant with same input and output parameters but have a short circuit fault detection feature unlike 9000Ex-32.

Features

- Intrinsically safe Associated Device

- Line fault detection (LFD)

- Compact DIN-Rail mount design of 17.6mm width

- High KV 3 port isolation

- High Accuracy, low drift, low temperature effect

- Low power dissipation

- Bi-Directional HART communication between the hazardous and non-hazardous area

Applications

- Used for I/P Converter, control valve and other field devices exposed to explosive atmosphere

- Transmitting control signals to transmitter measuring Temperature, Pressure or Flow

- Used in industrial automation

- Control of Valves Positioner in Hazardous area

- Monitoring and Controlling operation in potential explosive environment

- Prevents electrical noise, ground loops, and voltage spike